Urban’ALG

Pure air – Pure life

Urban-Alg focuses on the integration of microalgae-based systems within built and urban environments, where space and coexistence with existing infrastructure are key constraints.

It explores how biological processes can be adapted to dense contexts while maintaining stability and usability over time.

Urban’ALG principle

Removes CO2 and releases O2

Powered by natural Microalgae

Urban’Alg continuously treats the ambient air: the CO2 is fixed by photosynthesis and the O2 is released. The operation is continuous, with humidity (RH 90–98%), temperature (20–26 °C), and CO2 control by controlling the air flow.

A design that breathes, a technology that inspires.

Urban’ALG benefits

Microalgae Purification within our everyday environment

Improves air quality in car parks, stations, pedestrian areas

Creates visible ecological commitment

Based on 25 years of research & patents

Low maintenance & autonomous operations

Urban’ALG Key Performances

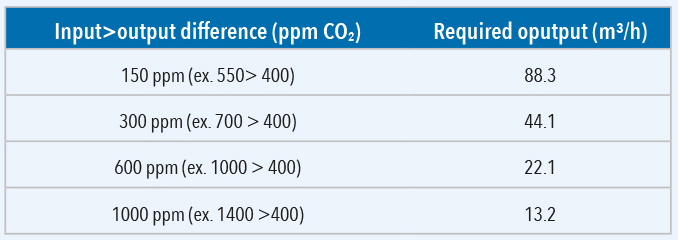

- Reduces 150–250 ppm CO2 in confined spaces

- Water consumption <1 L/day (NWT)

- Captures ~312 kg CO2/year

- Produces ~166 kg O2/year

Technical Information

- Active surface: 6.24 m² (12 plates)

- Capture factor: 10-50 kg CO2/m²/year

- Airflow: ~30 m³/h

- Nutrient medium: Adapted solution, delivered by misting

- Maintenance: weekly/monthly tasks

Urban’ALG Operating Conditions

Ambient Air Intake

The air is sucked in at the top and distributed through the Alium plates. The flow rate is sized so that the fixation capacity (≈ 26 g•h-¹ of CO2) is saturated without excess pressure drops

Operating Conditions.

The Alium support works by misting concentrated solutions (×100) derived from the BG-11 medium adapted to cyanobacteria. Micro-doses are provided according to the humidity of the substrate and the actual consumption (controlled by sensors). Target water consumption: 0.08–0.12 L•m-²•d-¹ (i.e., 0.5–0.8 L•d-¹ for 6.24 m²).

Medium Nutrient Intake

Misting is controlled by the humidity thresholds of the substrate and by an optical reflection/absorption measurement on control plates (replaces the turbidity of liquid media). Solenoid valves normally closed; anti-return; Periodic automatic rinsing.

Locations

The choice of location takes into account: clearances, fluid access (electricity, water), CO2 richness of the air, visual amenities and pedestrian access. Preliminary mapping of CO2-rich areas is recommended.

Sizing—Results

Assumptions: 12 plates (650 × 800 mm), total active area 6.24 m²; illuminance 250 μmol•m-²•s-¹; CO2 capture factor = 36.5 kg·m-²•year-¹; stoichiometry, photosynthesis 1 mol O2/1 mol CO2.

Technical Information

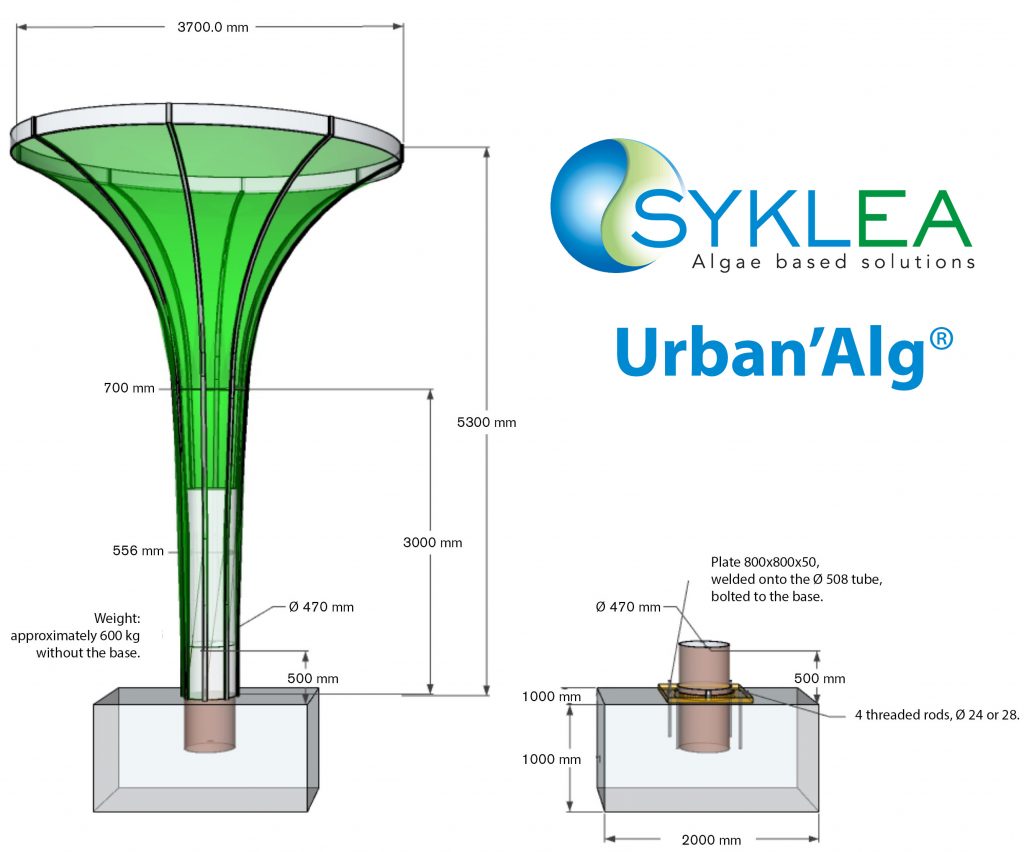

From the plan:

• Total height: ~5,580 mm; underside of canopy: ~5,000 mm.

• Crown diameter: ~3,514 mm (R ≈ 2,370 mm).

• Shaft: steel tube, usable section Ø ~470–540 mm.

• Base plate 800 × 800 × 50 mm, welded on Ø 508 tube, bolted to foundation.

• Anchoring: 4 threaded rods Ø 24–28 mm.

• Concrete foundation type 2,000 × 1,000 × 1,000 mm.

• Estimated mass of the superstructure (excluding foundation): ~600 kg.

• Frames available at top: 12 frames 650 × 800 mm ≈ 6.24 m² usable surface.

• The Alium plates (air/biomass exchange plates) are mounted in the frames and illuminated at 250 μmol•m-²•s-¹.

The biomass is kept moist by controlled misting; no free liquid is present.

1. Is a groundwater source required?

Only for filling and occasional top-up purposes.

2. Is the water supply active during winter, when temperatures are below zero?

Yes, we plan to include an electric heating system to prevent freezing.

3. Is the groundwater source suitable for use?

Yes, it is.

4. Can the water pipe be installed underground to prevent freezing?

Yes, this is recommended.

5. Can Urban’Alg include an electric heating cable to prevent freezing?

Yes, we can provide one. An electrical power supply is required.

6. Is electricity needed for each unit?

Yes. Power specifications: approximately 10 kW, 110 V, 60 Hz.

7. Is a communication system required?

Yes, a communication interface is needed to send data to the programmable logic controller (PLC), using IO-Link or bus mode communication.

8. Is there a maximum or minimum spacing between units?

No specific spacing is required; it mainly depends on aesthetic preferences.

9. Is there a minimum distance to maintain from aw building façade?

No, there is no minimum distance required.

10. Is there a minimum number of units needed for effective performance?

For optimal efficiency, we recommend installing one unit every 5–6 meters.

11. Are there accessibility requirements for maintenance?

Yes, maintenance access must be available around each Urban’Alg unit.

The choice of location takes into account: clearances, fluid access (electricity, water), CO2 richness of the air, visual amenity and pedestrian access. Preliminary mapping of CO2 -rich areas is recommended

Surverse

Not applicable – no free liquid in NWT technology. Condensate management by evaporation and/or micro-purging (a few mL/day).

(Misting) – Alium-BG

Composition : NaNO3 + K2HPO3, +MgSO4•7H2O+ CaCl2•2H2O+ Ctric Acid + citrate ferric ammoniacal + Na2CO3 + Na2EDTA

PH after dilution : 7 – 7,6

The Alium support works by misting concentrated solutions (×100) derived from the BG-11 medium adapted to microalgae.

Micro-doses are provided according to the humidity of the substrate and the actual consumption (control by sensors).

Target water consumption: 0.08–0.12 L•m-²•d-¹ (i.e. 0.5–0.8 L•d-¹ for 6.24 m²).

The stock solution is prepared in demineralized water, stored, and then diluted (1×) by the automaton at the time of misting.

An in-line static mixer ensures homogeneity.

The air is sucked in at the top and distributed through the Alium plates. The flow rate is sized so that the fixation capacity (≈ 26 g•h-¹ of CO2) is saturated without excess pressure drops.

Hypothesis et Utilisation parametres

• Species: Plectonema sp. (non-GMO cyanobacteria), immobilized on Alium support (NWT).

• Active surface: 6.24 m² (12 frames, 650 × 800 mm).

• Illumination: 250 µmol•m-²•s-¹ on plates.

• Temperature: 20–26 °C (22 °C nominal).

• Humidity: RH 90–98%.

• Capture factor: 36.5 kg CO2•m-²•yr-¹.

• Biomass productivity: 7.3–11 kg•m-²•yr-¹.

• Stoichiometry: 1 mol O2 / 1 mol CO2 (32 g O2 for 44 g CO2).