Carbon capture technology

SYKLEA process, a new brick after capture : C02 to fuel

Industrial facilities emit continuous streams of carbon dioxide under real operating constraints. Syklea develops microalgae-based industrial CO₂ capture systems that directly integrate with exhaust streams and convert carbon into valuable outputs. Our approach bridges biological carbon capture with industrial deployment, enabling sites to reduce emissions while creating resource value from captured CO₂.

CCS/CCUS

THE ACTUAL CO2 CAPTURE PROCESSES

> Energetic

> Uncertain

> Heavy water consumers

> Subject to risk

STEP 1: CO2 CCV ANALYSIS

WE DECODE YOUR EMISSIONS

Industrial emissions Input

Industrial smoke

Sampled at source

Pre-filtration gas conditioning

Temperature & particle control

Temperature & particle control

Data collection & processing

CO₂ concentration, gas mix profile, flow rate, pressure, etc

CO₂ concentration, gas mix profile, flow rate, pressure, etc

Treatment & industrial process

Biosynthesis parameters optimized to the gas stream

Biosynthesis parameters optimized to the gas stream

STEP 2: CO2 VALORISATION

WE CAN PRODUCE

Fuels

Biomass

Oxygen

Dry matter

Unlike storage-based solutions that generate no direct return, ALIUM produces value streams that offset costs and create profit potential. With an annual biomass yield of close to tons, the platform generates materials rich in proteins, lipids, and pigments that can be refined into products for specialty chemicals, bio-based industries, and sustainable agriculture. In addition, purified CO₂ can be supplied to commercial sectors such as greenhouses, beverage carbonation, and industrial processes.

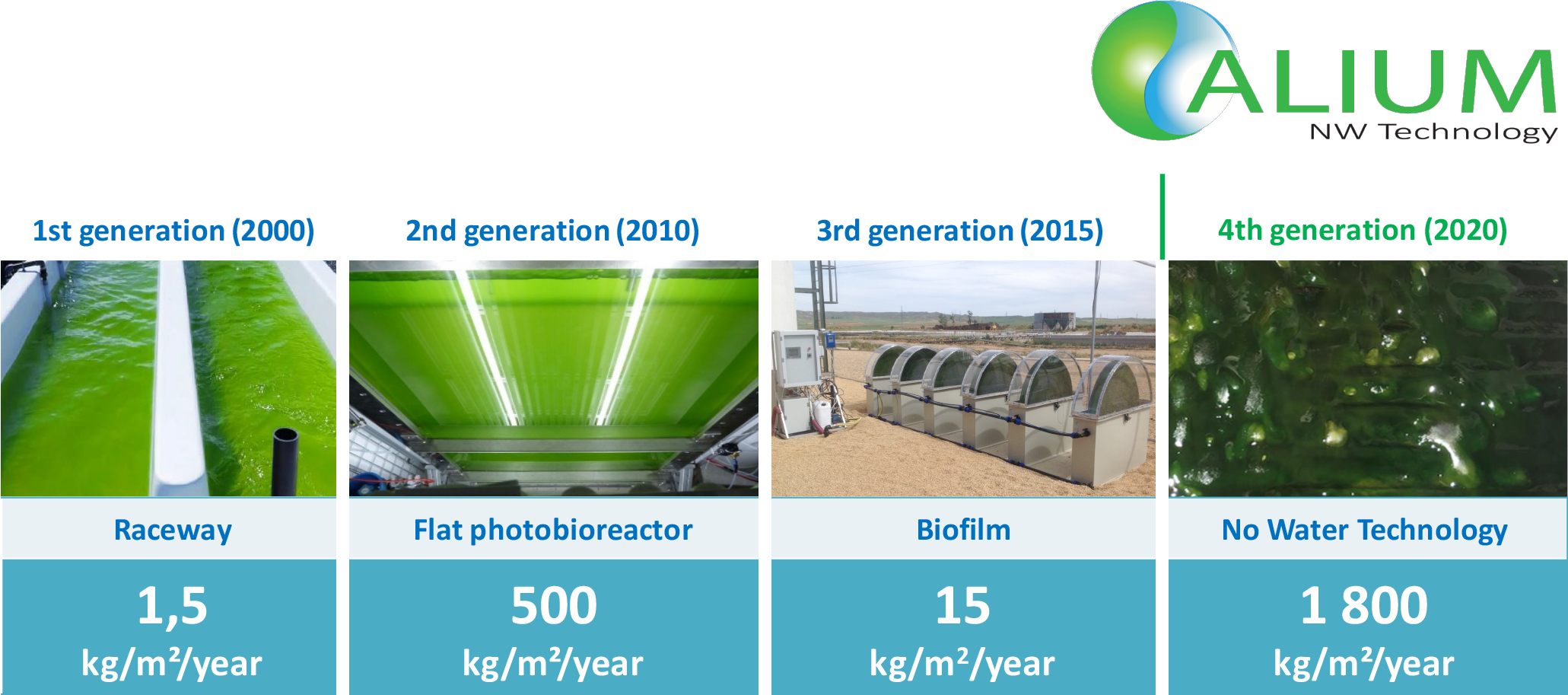

Summary of Microalgae C02 CU Technologies

STATE OF THE ART