ALIUM™ TECHNOLOGY

Transform emissions into valuable resources

Alium structures the way Syklea technologies move from research to industrial reality.

It defines a coherent framework where biological performance, engineering constraints, and industrial deployment are addressed together rather than separately.

Through Alium, Syklea aligns carbon capture, system stability, and scalability within a single platform designed to evolve from pilot validation to long-term operation.

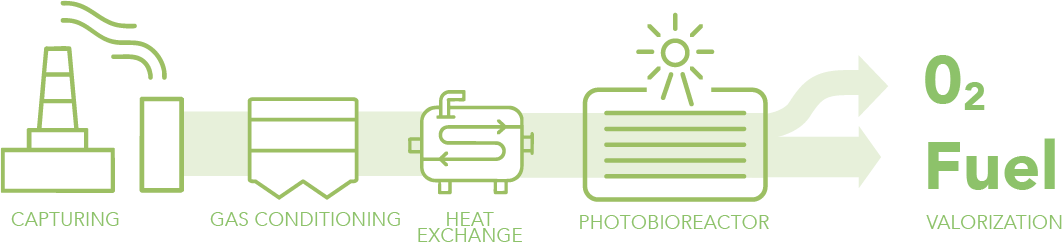

CO2 Valorisation

ALIUM® is SYKLEA’s proprietary industrial technology that transforms carbon dioxide emissions into valuable resources using advanced photobioreactor systems and engineered microalgae processes.

Designed for large-scale deployment, ALIUM redefines carbon capture: not just eliminating emissions, but also converting them into usable outputs that fuel industrial innovation and sustainability.

ALIUM is not a conventional carbon capture system. It is a biological refinery, capable of turning flue gases into profitable assets. This approach combines the capture of resources with their transformation, providing industries with a sustainable and eco-friendly pathway. With every ton of CO2 processed, ALIUM moves us closer to a circular industrial model where emission fuel growth does not decline.

Alium Key features

- Integration with flue gas systems: ALIUM® connects directly to industrial stacks, capturing emissions at the source.

- Multi-stage gas conditioning: SO2, NOx, and particulate matter are scrubbed to create a clean CO2 feedstock.

- High-performance photobioreactors: Engineered for light penetration, gas transfer, and controlled growth cycles to maximize conversion efficiency.

- No Water Technology (NWT): A closed-loop nutrient and liquid management system eliminating the need for freshwater input.

- Output valorization: Biomass and chemical derivatives can be refined into industrial feedstocks, while purified CO2 supports further utilization pathways.

- Scalability and modularity: Units are designed for progressive scale-up, from pilot installations to full industrial clusters.

Benefits

ALIUM™ enables industries to turn carbon into value streams:

ALIUM™ enables industries to turn carbon into value streams:

Reduce carbon footprint

Generate new revenue streams

Produce high-value outputs: proteins, lipids, pigments, purified CO₂

By linking environmental performance with economic incentives, ALIUM™ makes sustainability a driver of competitiveness. Each ton of CO₂ captured is not just avoided—it is transformed into products that can enter profitable markets.

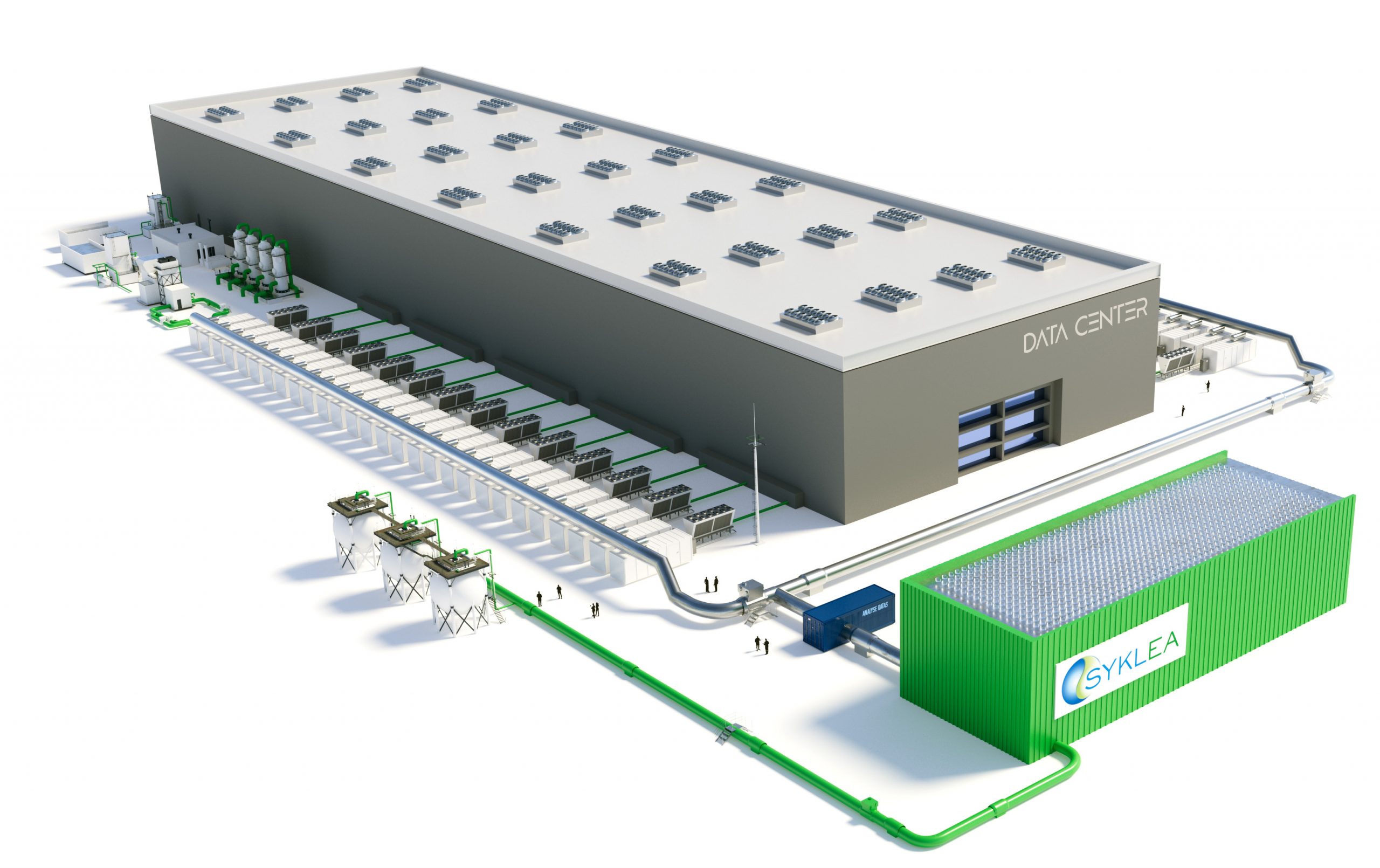

Industrial Deployment

Licensing & installation

Modular units for scale-up

Optimized operating costs

Capturing 500,000 tons of CO₂ per year requires robust infrastructure. ALIUM™ provides a complete, modular system covering capture, biological conversion, and product valorization.

Deployment at this scale involves flue gas conditioning units, integrated photobioreactor clusters, and downstream processing facilities. Unlike conventional solutions that end with storage, ALIUM™ integrates conversion and product pathways, ensuring both decarbonization and value creation.

From Costs to Returns

Unlike storage-based capture, ALIUM™ creates measurable financial returns.ALIUM® is designed not only as a carbon capture solution but as a profitable platform. The financial benefits of investing in this technology at a scale of 10,000 tons of CO2 per year are demonstrated, showing how it can provide tangible financial returns while achieving decarbonization objectives.

ROI <4 years

O2

5,100,000 m3/year

Oil

3200 t/year

Biomass

9000 t/year

LIPID

10 M€/year

CH4

1 000 000 m3/year

NOx Zéro cost

for treatments

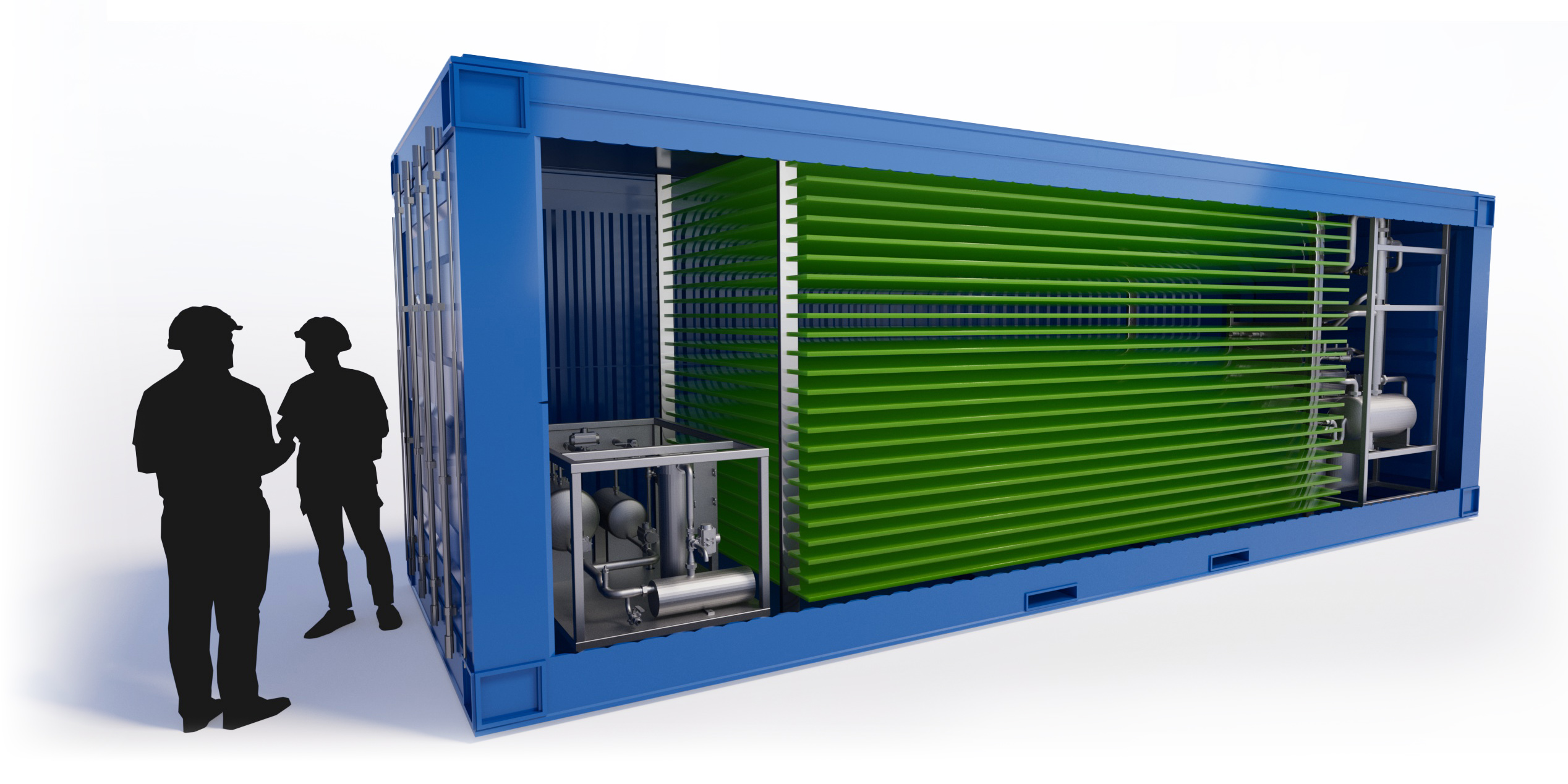

Proof of Concept (POC)

Before full-scale deployment, ALIUM™ can be validated on-site with a containerized pilot unit.

The POC reproduces, on a smaller scale, the exact conditions of an industrial plant. It reduces risk, secures real-world data, and provides stakeholders with the confidence to invest in large-scale deployment.

The POC provides:

Process & biological studies

Real flue gas treatment

Measurable yields (oxygen, hydrocarbons, biomass)

Scale-up validation & final technical/financial report

STEP 1

Installation Container

STEP 2

Flue gas assessment

STEP 3

Data

processing

STEP 4

Industrial design study

STEP 5

Final equipment deployment